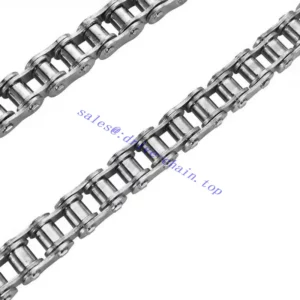

Single row side length extension pin roller conveyor drive attachment chain

As one of the drive chain manufacturers, suppliers, and exporters of mechanical products, We offer drive chain and many other products.

Please get in touch with us for details.

Mail:[email protected]

Drive Chain

Drive chains are an essential component of many industrial and mechanical systems. They provide a reliable means of transmitting power from one rotating shaft to another, allowing for smooth and efficient operation of machinery. Whether you're looking to build a new system or replace an existing chain, choosing the right drive chain is critical to achieving optimal performance and durability.

At its most basic level, a drive chain consists of a series of interconnected links that rotate around a sprocket to transfer power. These links are typically made of high-strength steel, and are designed to withstand the stresses of high-speed rotation and heavy loads. The links are held together by pins and bushings, which allow them to pivot and flex as they move around the sprocket.

One of the key factors to consider when selecting a drive chain is its pitch, which refers to the distance between the centers of adjacent links. Pitch can vary depending on the application and the size of the sprockets being used. In addition to pitch, other important factors to consider include the chain's tensile strength, fatigue resistance, and wear resistance.

Drive Chain Specifications

|

Compare data |

KLHO | The others |

| Forging process | Forged through multiple processes, anti-wear and tensile, not easy to break | Direct processing of raw materials, easy to break and not firm, easy to corrode |

| heat treatment | Carburizing and quenching treatment, high surface hardness, long service life | General heat treatment, poor hardness, there will be obvious cracks after bending |

| Chain plate thickness | Raw material customized chain plate thickness, high thickness, strong tensile capacity, durable | The chain plate is thinner, saving cost. Not wear-resistant, easy to break and affect operation |

Drive Chain Benefits

High efficiency: Drive chains are very efficient at transmitting power. They can transmit up to 98% of the power that is applied to them. This means that less energy is wasted, which can save you money on your operating costs.

Durability: Drive chains are very durable. They can withstand a lot of wear and tear, making them a good choice for applications where high loads or harsh conditions are present.

Versatility: Drive chains can be used in a wide variety of applications. They are commonly used in industrial machinery, automotive engines, and bicycles. This makes them a very versatile option for power transmission.

Low maintenance: Drive chains require very little maintenance. They can typically go for many years without needing to be replaced. This can save you time and money on maintenance costs.

Uses Of Drive Chain

Bicycles: Drive chains are used to transmit power from the pedals to the rear wheel in bicycles.

Motorcycles: Drive chains are used to transmit power from the engine to the rear wheel in motorcycles.

Engines: Drive chains are used to transmit power from the crankshaft to the camshaft in internal combustion engines.

Industrial machinery: Drive chains are used in a wide variety of industrial machinery, such as conveyor belts, printing presses, and milling machines.

Agricultural machinery: Drive chains are used in a variety of agricultural machinery, such as tractors, harvesters, and balers.

Construction machinery: Drive chains are used in a variety of construction machinery, such as excavators, bulldozers, and cranes.

Other: Drive chains are also used in a variety of other applications, such as lawnmowers, snowblowers, and vending machines.

Maintenance tips for Drive Chain

Inspect the chain regularly. Look for signs of wear, such as stretched links, missing pins, or damaged rollers. If you see any of these signs, it's time to replace the chain.

Clean the chain regularly. Dirt and grime can build up on the chain and cause it to wear out prematurely. Use a mild detergent and water to clean the chain, and be sure to dry it thoroughly before reassembly.

Lubricate the chain regularly. Lubrication helps to reduce friction and wear, and it also helps to keep the chain clean. Use a high-quality chain lube and apply it according to the manufacturer's instructions.

Adjust the chain tension regularly. The chain should be tight enough to prevent it from slipping, but not so tight that it puts undue stress on the sprockets. Check the chain tension regularly and adjust it as needed.

Store the chain properly when not in use. If you're not going to be using the chain for a while, store it in a clean, dry place. This will help to prevent it from corroding or rusting.

We are one of the best drive chain manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!